Structural LVL (Laminated Veneer Lumber) is an engineered wood product that offers superior strength-to-weight ratio compared to traditional timber, making it ideal for load-bearing applications in modern construction projects.

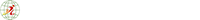

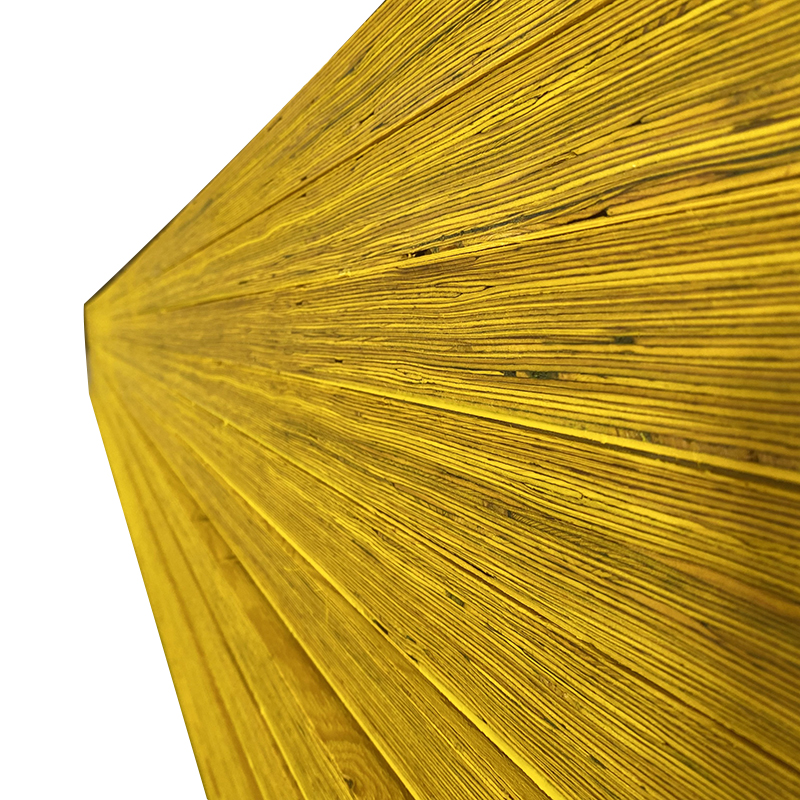

The manufacturing process of structural LVL involves bonding multiple thin wood veneers with moisture-resistant adhesives under heat and pressure, creating a uniform material with predictable performance characteristics.

Why Structural LVL is Becoming

Go-To Choice for Large-Span Buildings

Structural LVL beams can support up to 2.5 times more weight than conventional timber of the same size, allowing architects to design longer spans without additional support columns.

The Environmental Advantages of Structural LVL in Sustainable Architecture

Unlike natural timber, structural LVL eliminates natural defects such as knots and grain variations, ensuring consistent structural integrity throughout the entire beam length.

Structural LVL vs Steel: A Lightweight Champion with Comparable Strength

The dimensional stability of structural LVL makes it resistant to warping, twisting, and splitting, even when exposed to varying moisture conditions on construction sites.

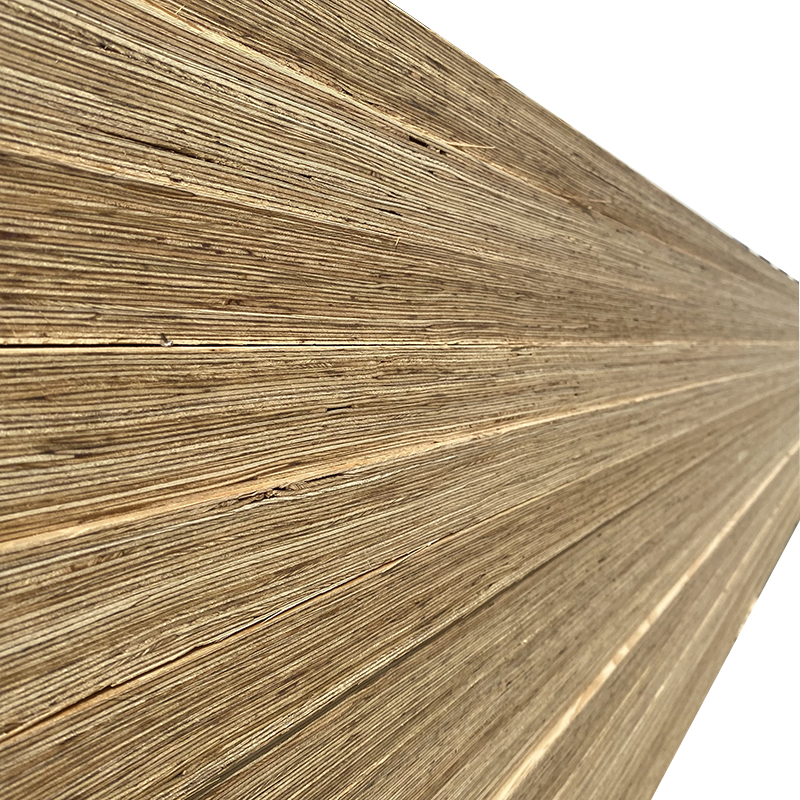

Structural LVL is manufactured using fast-growing plantation trees, making it a sustainable alternative to traditional lumber while reducing pressure on old-growth forests.

The lightweight nature of structural LVL simplifies installation processes, reducing labor costs and construction timelines compared to heavier steel or concrete alternatives.

Structural LVL can be manufactured in lengths exceeding 9.5 meters, enabling the creation of large open spaces in commercial buildings, sports facilities, and residential projects.

Despite being 20-40% more expensive initially than traditional timber, structural LVL offers long-term cost savings through reduced maintenance requirements and extended service life.