Product Name

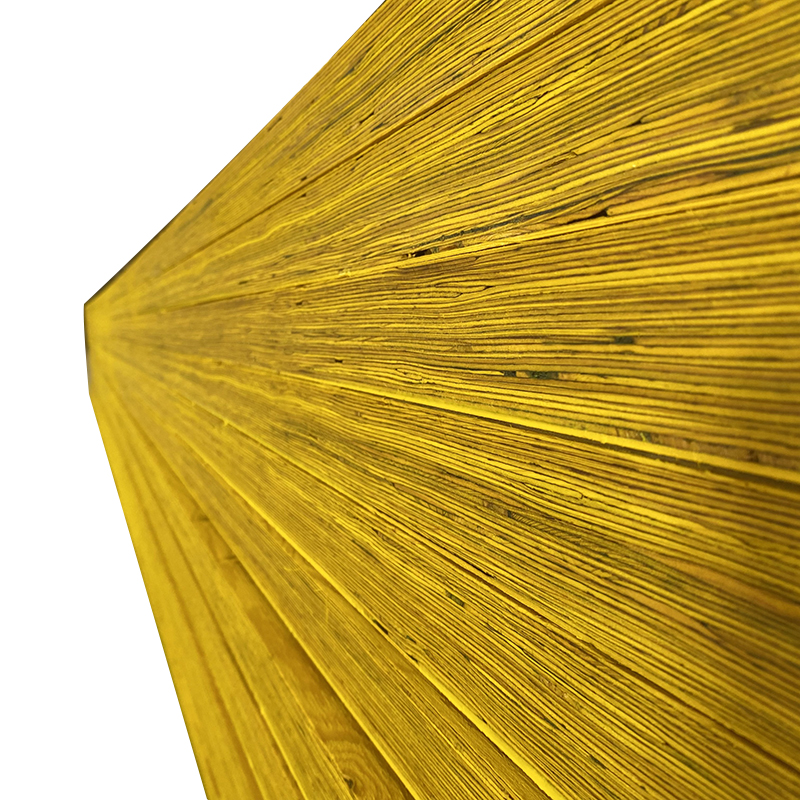

Structural Laminated Veneer Lumber (LVL) – 45×90 mm

Dimensions

Thickness: 45 mm

Width: 90 mm

* Length: Length: Standard lengths include 3.6 m, 4.2 m, 4.8 m, 6.0 m, up to 9.5 m (standard lengths include 6000 mm, 8000 mm, etc.)

Material

Wood Species: Radiata Pine / Larch

Adhesive: Phenolic WBP glue (A-grade, waterproof)

Density: ~720–730 kg/m³

* Moisture Content: 8%–15%

Standards & Compliance

Standard: AS/NZS 4357 (Australia/New Zealand structural LVL standard)

Formaldehyde Emission: E0 / E1 / E2 compliant

* Treatment: H2 treatment available (termite-resistant)

Mechanical Properties

High bending strength

Strong nail holding capacity

Tight construction and high load-bearing capacity

* Suitable for structural applications like beams, framing, and scaffolding

Applications

Use Cases: Beams, wall framing, scaffolding boards, formwork systems

* Suitable for: Indoor and outdoor structural use

Packaging & Delivery

Packaging: Palletized

Minimum Order: 1×20′ FCL (~20 CBM)

* Lead Time: ~7 days (depending on quantity)

🔧 Structural Grade

Grade: E13.2 or F17 (depending on supplier)

* Treatment: H2-S (termite-treated, 25-year guarantee)

📋 Standards & Certification

AS/NZS 4357: Structural LVL standard (Australia/NZ)

FSC Certified: Available

* H2-S Treatment: Optional, with 25-year termite protection guarantee

📎 Optional Services

Custom stamping

Private labeling

H2-S or H3 treatment

Length color-coding for easy ID on-site

⚙️ Mechanical Properties

| Property | Value Estimate (E13.2 Grade) |

| Bending Strength (Fb) | ~48 MPa |

| Modulus of Elasticity (E) | ~13.2 GPa |

| Shear Strength | ~5.5 MPa |

| Compression (perpendicular) | ~12 MPa |

Note: These are typical values for E13.2 LVL. For F17 grade, strengths are ~10–15% higher.

🧮 Load Capacity (Span Table Reference)

For 90×45 mm LVL, simply supported, single span, uniformly distributed load (UDL):

| Span (m) | Max UDL (kN/m) | Load Case (Residential) |

| 2.4 | 6.5 kN/m | Floor joist (L/360 deflection) |

| 3.0 | 4.2 kN/m | Floor joist |

| 3.6 | 2.9 kN/m | Floor joist |

Assumes E13.2 grade, residential loading (1.5 kPa live + 0.5 kPa dead).

For roof members, allowable spans are longer depending on load case.

- Structural Performance Evaluation of LVL Beams under Varied Load Conditions

- Design Guidelines for LVL Members in Residential and Commercial Construction

- Load-Bearing Capacity Analysis of Structural LVL Beams: A Comparative Study

- Long-Term Deflection Behavior of LVL Joists in Timber Floor Systems

- Application of AS/NZS 4357 Standards in Structural LVL Manufacturing and Design

- Shear and Bending Strength Characteristics of LVL with Different Veneer Grades

- Moisture Effects on Structural Properties of LVL under Service Conditions

- Lateral Stability of Deep LVL Beams in Timber Frame Construction

- Structural LVL vs. Glulam: A Technical Comparison for Beam Applications

- Fire Resistance and Char Rate Analysis of Structural LVL in Building Elements

These LVL beams are factory-finished with a protective spray paint coating, designed to enhance both aesthetic appeal and durability in exposed or semi-exposed applications. The paint system is specially selected to adhere to engineered wood surfaces and withstand environmental exposure.

- Base Material: High-grade structural LVL (e.g., E13.2 or F17)

- Surface Finish: Spray-applied acrylic or enamel paint system

- Color Options: Available in standard or custom colors (light colors recommended for exterior use)

- Treatment Compatibility: Suitable for LOSP or Tru-Core H3-treated LVL

- Durability: Enhanced UV and moisture resistance when properly maintained

Structural pine LVL beams manufactured to AS/NZS 4357 are engineered wood products formed by bonding rotary-peeled Radiata-pine /Larch-pine veneers with a phenolic Type A waterproof adhesive; compliance with the standard requires continuous production monitoring, in-grade structural testing and a product-specific set of published strength/stiffness values, giving designers a reliable, straight-spanning alternative to sawn timber that is recognised in Australia’s National Construction Code .