Description

—-

1. Product Definition & Manufacturing

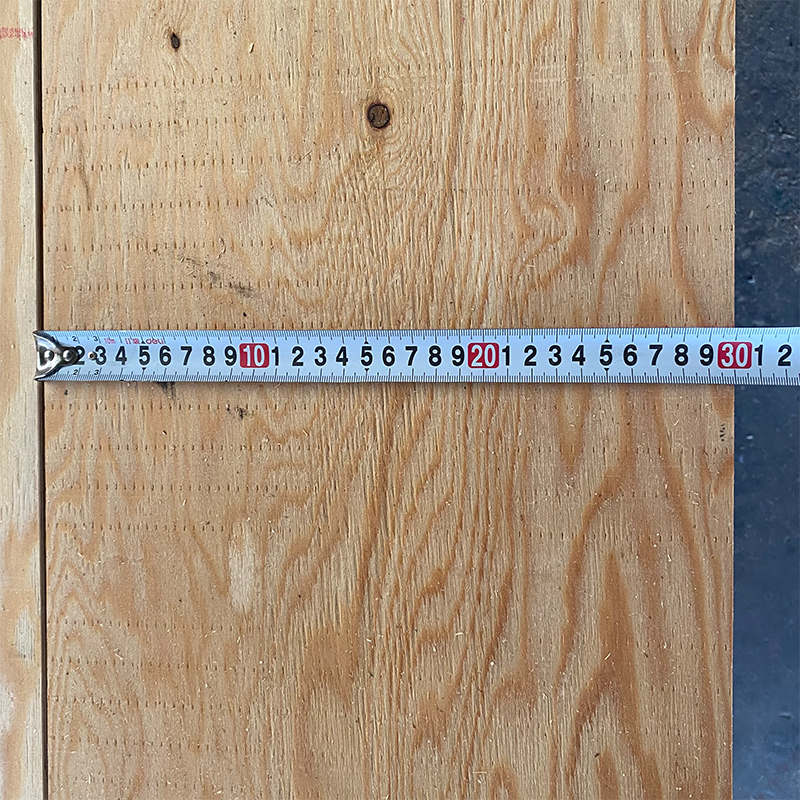

Laminated Veneer Lumber (LVL) is an engineered wood product manufactured by bonding 3 mm rotary-peeled veneers (Douglas-fir, Southern pine, larch or poplar) with weather-resistant phenolic adhesive under heat and high pressure. All veneers are grain-aligned in one direction to maximise bending strength and stiffness; defects are dispersed, producing an exceptionally homogeneous billet that can be sawn into almost any length (up to 24 m) or thickness (38–90 mm) .

—-

2. Key Performance Attributes

• High strength-to-weight ratio: Twice the strength of steel by weight; design values are predictable and code-listed .

• Dimensional stability: Factory-dried (≈10 % MC) so shrinkage, warping and checking are negligible on site .

• Workability: Can be sawn, drilled, nailed or bolted with ordinary carpentry tools; zero waste from knot removal .

—-

3. Primary Construction Applications

• Beams, headers, lintels, ridge beams – residential & commercial .

• Floor & roof joists, rafters, purlins, hip/valley members – including long clear spans .

• Flange stock for prefabricated wood I-joists (major end-use) .

• Columns, wall studs, shear walls in mid-rise timber buildings .

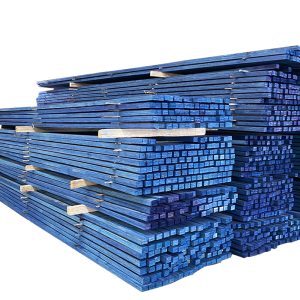

• Concrete formwork beams & soldiers, scaffolding planks, truck decking – orange colour-coded grades available .

• Modular / off-site construction: precise, pre-cut LVL cassettes speed erection and reduce site labour .

Laminated Veneer Lumber delivers steel-like strength, concrete-competitive spans and wood’s sustainability in one engineered product. It is the go-to material whenever structural reliability, long clear spans or weight savings are paramount in modern wood-frame, hybrid or mass-timber construction.

—-

Reviews

There are no reviews yet.