AS/NZS 4357.0 STRUCTURAL LVL: F17 (E14) & F11 (E10) FROM 14-YEAR MILL

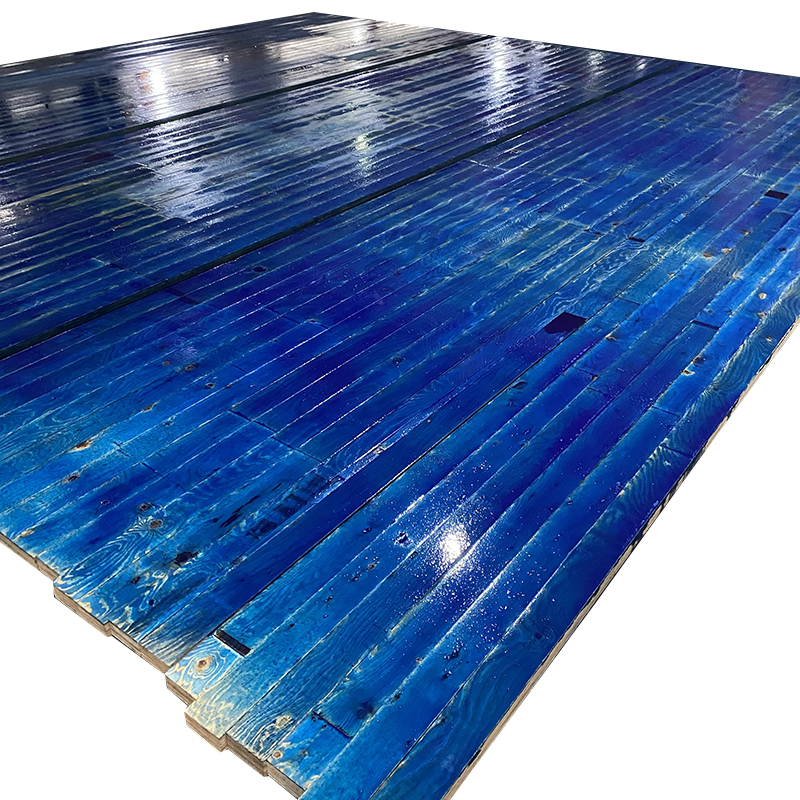

72-HOUR BOIL-PROOF SCAFFOLD BOARDS – WBP PHENOLIC, BSI BMP 773486

LONG-SPAN LVL BEAMS DELIVERED TO SITE

SYD/MEL/BNE

Manufactured in our 14-year specialized LVL plant, every F17 (E14) beam is built from select larch & radiata pine, bonded with WBP phenolic resin that survives 72-hour boiling. The result is a predictable, straight member that delivers three times the bending strength of solid timber and meets the toughest clauses of AS/NZS 4357.0.

F17 Structural LVL – Quick Spec Sheet (AS/NZS 4357.0)

Grade: F17

Characteristic bending strength (fb): 65 MPa

Characteristic shear strength (fs): 6.8 MPa

Characteristic compression ⊥ (fc,⊥): 21 MPa

Characteristic compression ∥ (fc,∥): 45 MPa

Mean modulus of elasticity (E): 14,000 MPa (hence “E14”)

5th-percentile modulus (E0.05): 12,300 MPa

Characteristic density: 730 kg/m³

Standard section tolerances: ±0.5 mm thickness / ±1 mm depth

Maximum stocked length: 9.5 m (custom cut)

Moisture content at dispatch: 10–12 %

Treatment: H2-S (LOSP) or H3-HW (CCA/ACQ) – 25 yr above ground / 50 yr enclosed

Adhesive bond: WBP phenolic – 72 h boil-proof (AS/NZS 2098.7 pass)

Fire char rate: 0.60 mm/min (AS 1720.4)

Fastener: 75 % of nailed steel capacity vs. solid pine

Need long spans without mid-support? Our Structural LVL is custom cut up to 9.5 m on precision German saws, then kiln-finished to 12 % moisture for minimal on-site shrink. Architects specify it for clear-span auditoriums, car-showroom roofs and mezzanine floors because it behaves like steel at a fraction of the weight.

Termites and Australian weather are no match for our H2/H3 treated LVL. The LOSP dual-treatment penetrates to the core, giving a 50-year durability rating above ground and 25 years in-ground, fully backed by BSI BMP 773486 certification. You build once; the frame stands for generations.