PROJECT DETAILS

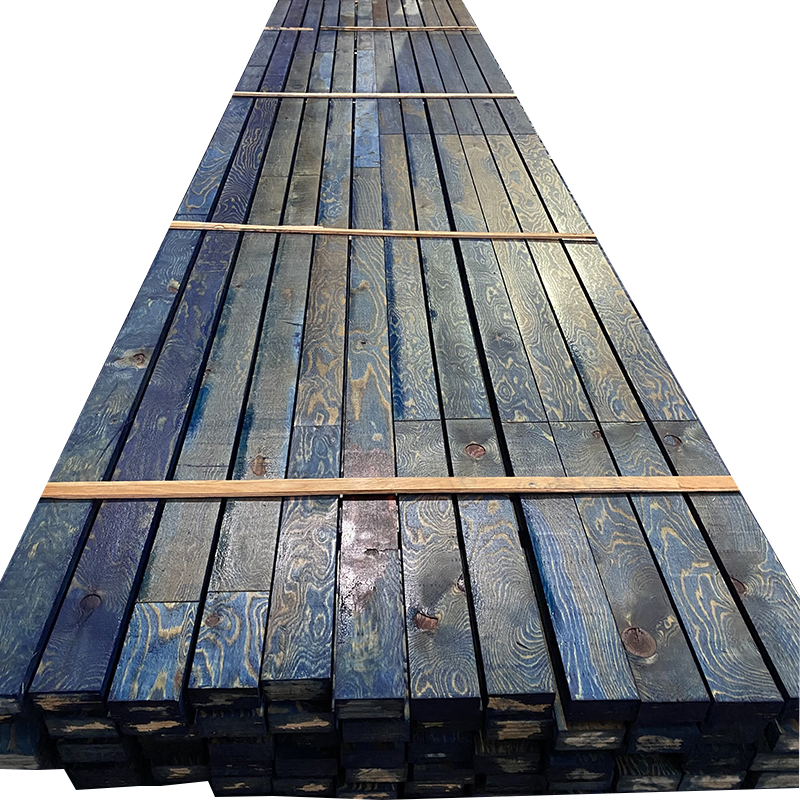

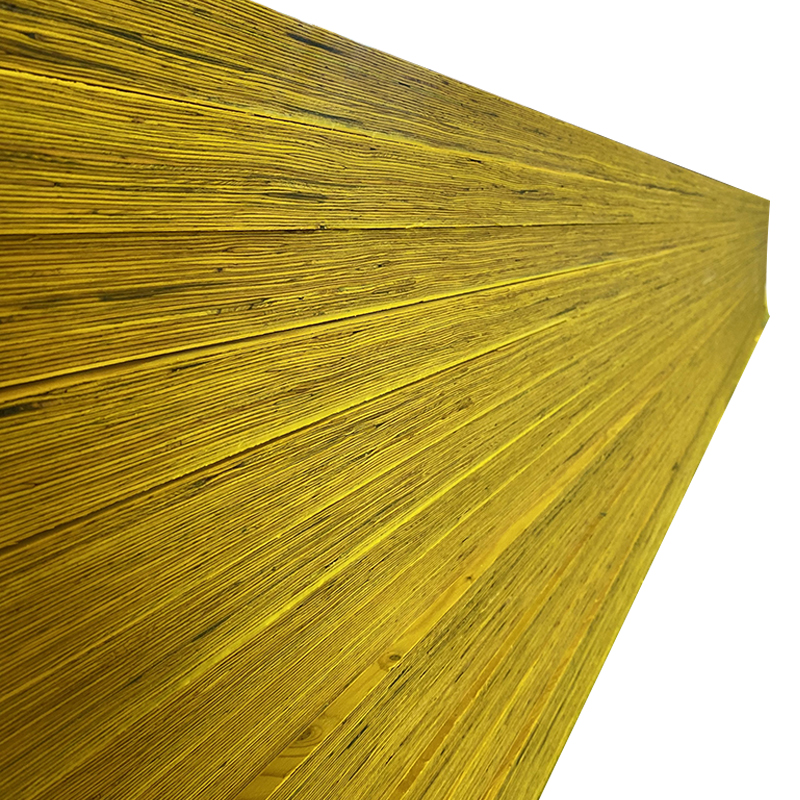

A1: “STRUCTURAL LVL” stands for Laminated Veneer Lumber that is specifically designed and certified for load-bearing and structural use in construction. It is an engineered wood product made by bonding thin wood veneers together under heat and pressure, with the grain of each veneer running parallel to the longitudinal axis. This gives LVL high strength, stiffness, and dimensional stability, making it suitable for beams, headers, joists, and other structural components.

Use: LVL beams act as temporary or permanent load distributors between timber upper floors and concrete podiums.

Advantage: Lighter than steel, reduces crane demand and foundation load.

Top-Hat Trusses for Roof-Level Plant Rooms

- Use: Support HVAC units, water tanks, or elevator machine rooms on rooftops.

- Advantage: LVL’s high stiffness (E ≈ 14 GPa) limits deflection under dynamic equipment loads.

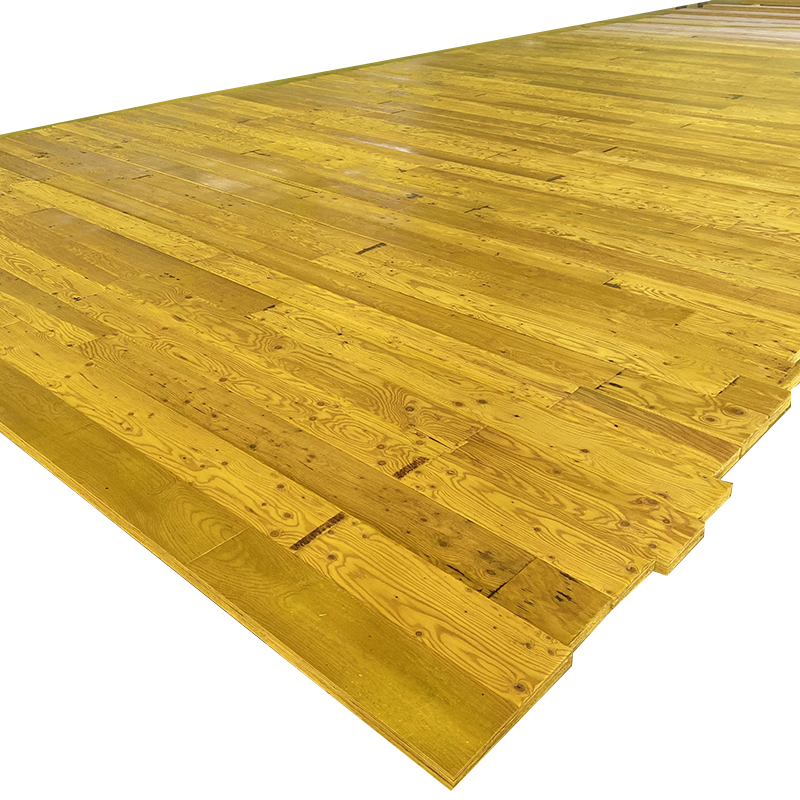

Façade Support Sub-Frames

- Use: LVL is used in secondary framing systems to support cladding panels (e.g., terracotta, fiber cement).

- Advantage: Thermal break effect compared to aluminum; simplifies fixing with wood screws.

Perimeter Safety Screens

- Use: LVL walers and posts support climbing protection screens during vertical construction.

- Advantage: Lightweight, reusable, and easy to cut on-site for custom fit.